Table of Contents

Other 3D printers owned by the space

The following printers have either been built by members on behalf of 57North, or have been received as donations. Details are listed below. Unless otherwise stated, the kit described here is stowed in the space, on the built wall unit near the power utility cupboard.

What's with the weird names? Since the FormLabs machines have playful names baked in their firmware, the author has made up names for the non-FormLabs machines for consistency. We can rename as needed.

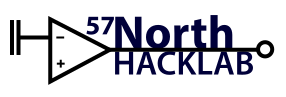

Form 2 "Shark"

Manufacturer: FormLabs (purchased from new in approx 2018).

Source: Donated to the space, 17/01/2021.

Summary: SLA 3D printer; very high max resolution (25 microns); resin print material is expensive; needs cleaning; leaks but is working pending light maintenance.

State: Working. All parts to successfully print are present, together with a full cartridge of clear FormLabs resin. The machine powers on with no errors. There are visible signs of a resin leak (confirmed from former owner). Early investigations hint that may be an alignment issue between the cartridge (located on the spine behind the orange lid) and the resin releaser mechanism directly under the cartridge that dispenses into the resin tank.

The previous owner reports the machine is reliable, once maintenance has been performed.

In order to be able to print, the following maintenance steps will be required first:

- Heavy clean of the inside surfaces and tank area with IPA

- Investigation in source of leak (to prevent future mess during storage).

- Replacement of cartridge with new one (supplied)

After-print care washing is needed for prints from this printer. This consists of a bath of either IPA or similar solvent. A washing tank is recommended to address COSHH concerns.

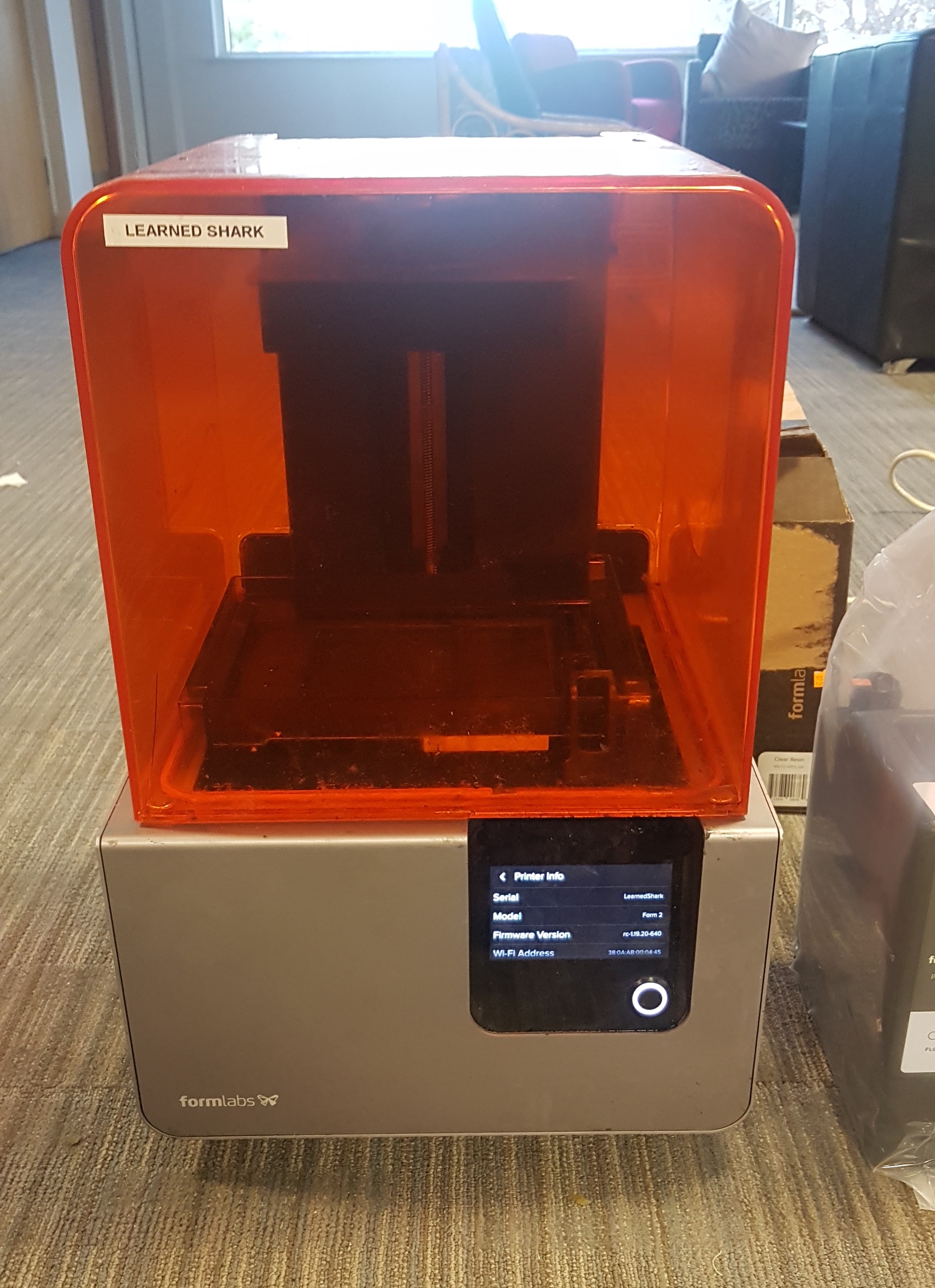

Form 2 "Kitty"

Manufacturer: FormLabs (purchased from new in approx 2015).

Source: Donated to the space, 17/01/2021.

Summary: SLA 3D printer; very high max resolution (25 microns); resin print material is expensive; parts missing; internal issue

State: Not working. The printer is missing a build platform along with the resin tank. A replacement resin tank is included but requires fitting. A new build platform will need to be purchased. The printer turns on and passes the self-check, but grinds an internal gear as it performs it's test movements. It is unknown if this is caused by absence of a resin tank or is an issue with the internal UV laser assembly. UPDATE: Looks increasingly like it's the former.

In order to be able to print, the following maintenance steps will be required first:

- Investigation into the source of internal grinding (to determine if printer is still viable)

- light clean of the inside surfaces with IPA

- Installation of the supplied resin tank

- sourcing and fitting of a replacement built platform (approx £90)

- sourcing and fitting of new resin cartridge (approx £140)

After-print care washing is needed for prints from this printer. This consists of a bath of either IPA or similar solvent. A washing tank is recommended to address COSHH concerns.

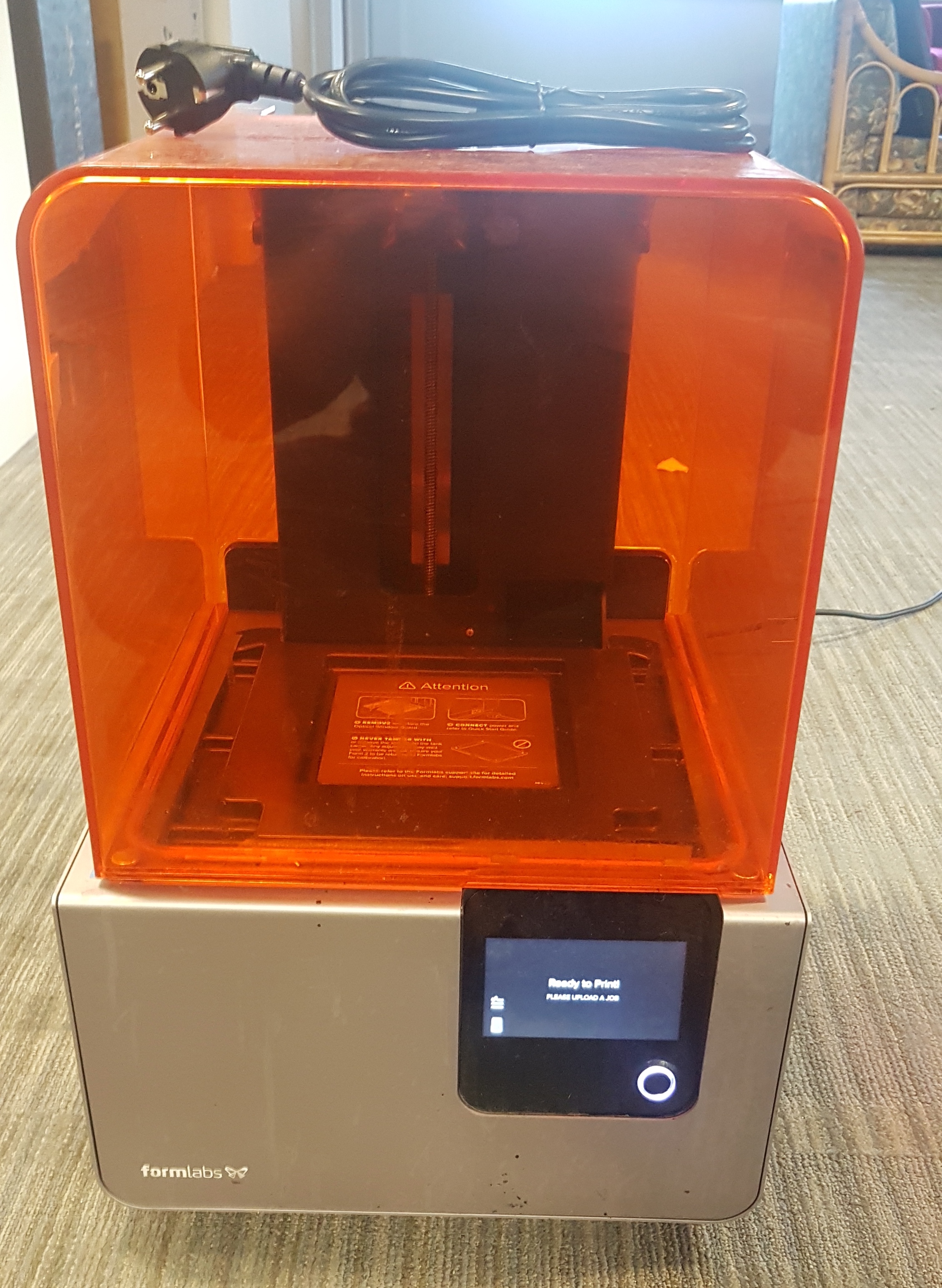

Manufacturer: Ultimaker

Source: Donated to the space, 17/01/2021.

Summary: Single extruder FDM printer; 2.85mm filament; y-axis grinding; rods lacking grease; screen degraded; needs cleaning and lubricating; not working.

State: Machine powers on, reports temp errors and grinds gears on auto-home. The printer has very jerky movement and is pretty dirty/dusty from use and storage. The LCD screen has a faded area but is mostly readable. When working, prints can be started via USB or via SD card. Printer has a vintage quality, being an all-wood early Ultimaker.

In order to be able to print, the following maintenance steps will be required first:

- Rods in need of greasing

- surfaces require cleaning

- Reel dispensing solution required

- Hot-head servicing or replacement

- end-stop servicing or replacement

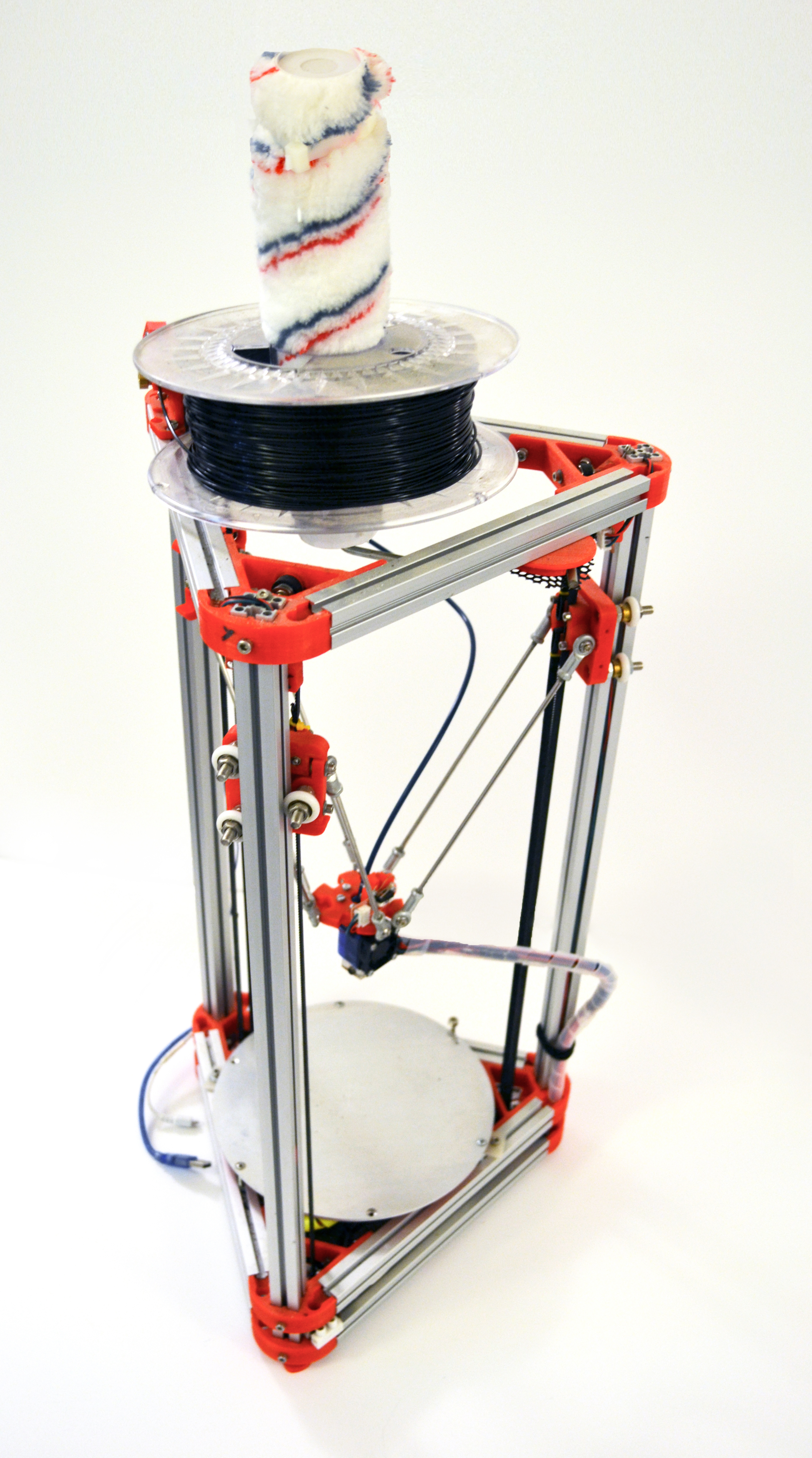

Kossel Mini "Webster"

Manufacturer: Kwuson kit build, built by space members

Source: Ebay, kit purchased 05/05/2016

Location: Currently stowed on floor by the side of the 3D printer desk location in the space.

Summary: Single extruder delta FDM printer; 1.75mm Filament; uses OctoPi; small print area; working but experiences occasional TEMP ERROR and shut-off during print.

State: The machine powers on and prints via wifi using the onboard OctoPi installation. The print area is small due to bed-leveling limitations (printable area drawn on bed itself). Manual 3-point bed-levelling is done using the GUI to position. Fast or fine detail prints are not recommended. The 12v 30A power supply has been repurposed and may need to be replaced.

In order to be able to print, the following maintenance steps will be required first:

- Investigate/fix source of occasional TEMP ERROR shutoff (loose thermistor wiring, at a guess)

- Manual bed re-levelling (upgrading to BLtouch-driven autoleveling would be a vast improvement)

- Source a power supply

UPDATE 22/01/21: Alternative power supply located. Drop-off at space pending.

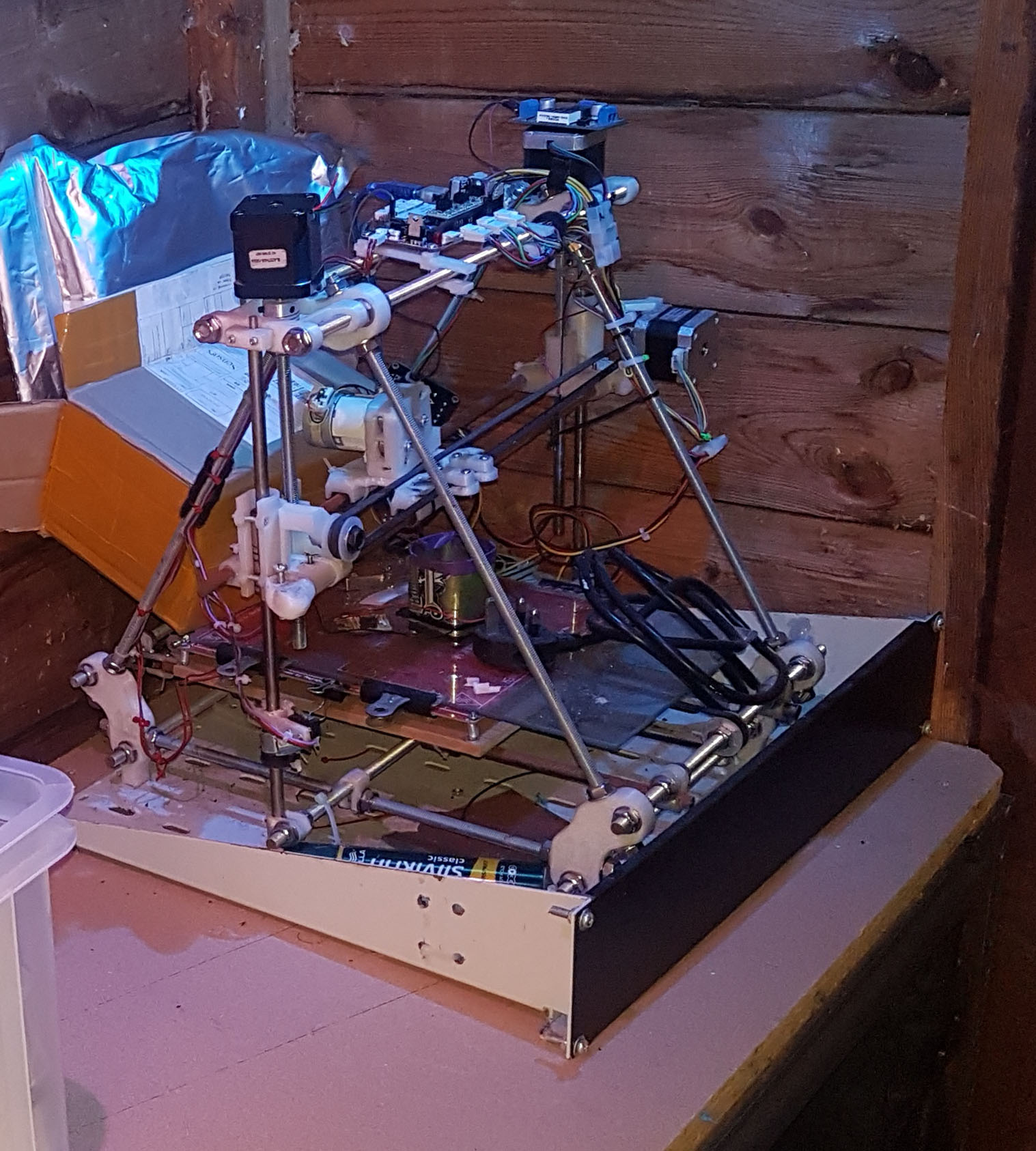

Reprap Prusa Mendel "Arthur"

Manufacturer: Built by members, build started in 2014

Source: [https://reprap.org/wiki/Prusa_Mendel]

Location: Currently stored at a member's home address, boxed and ready for relocation

Summary: Space-made with DIY components; 1.75mm Filament, rather hacky; Hothead issues; Working pending head rebuild.

State: Unused for some time. Head has been recently rebuilt using reprinted carriage head and new hothead [21/03/21]. Previously, the main board (Sanguinoliu 1.3a) failed due to over-heating problems at the PID hot-bed power output. The board's bed PID power FET has been bypassed with the 5v logic directly driving an external relay for bang-bang bed control. The XYZ mechanics are working. Manual bed-levelling lacks precision, but is functional. Recommend inverting the leveling bolt/nut and adding a 3d Printed knob to the nut for easier levelling (Like the Ender3).

In order to be able to print, the following maintenance steps will be required first:

- Sourcing of power supply

- Manual levelling improvements (ideally)

Misc other items

Manufacturer: Varied

Source: Donated to the space, 17/01/2021.

Summary: 3 boxes of 2.85mm PLA/ABS filament spools, various colours; contents yet to be itemised.

State: Between 6 and 12 spools. More than half of the spools have been exposed to air for an undisclosed time, and so may have absorbed moisture. The filament spools can be refurbished by heating the reels to no more than 50C in a conventional oven for a few hours (source).

It would be good for someone to itemise these at some point.